Table Of Content

In 1842, John Herschel—astronomer, photographer, and chemist—created the cyanotype process of blueprinting. This process occurred by drawing on semi-transparent paper over another sheet of paper and applying photosensitive potassium ferricyanide and ferric ammonium citrate mixture. The drawing was then exposed to light, turning the exposed paper blue and leaving the drawing lines white. Computer-aided design touches so many aspects of our everyday world, it’s hard to measure.

Baked-In Security: How DevSecOps Can Protect Software Supply Chains

What is an engineering bill of materials (EBOM)? Definition from SearchERP - TechTarget

What is an engineering bill of materials (EBOM)? Definition from SearchERP.

Posted: Mon, 07 Feb 2022 21:54:09 GMT [source]

This has led to enhanced quality in manufactured goods and streamlined planning of them. CAD is used in industrial design to create sleek and functional product designs, integrate with other design tools, and streamline manufacturing processes. CAD has revolutionized the way designs are created by providing faster and more accurate results compared to traditional manual drafting methods.

The 2000s: Platform Availability and CAD/CAM Integration with Fusion 360

Accurate, high quality visualizations – The main advantage is that CAD software allows you to visualize designs and projects by creating highly accurate, lifelike 2D and 3D models. This is vital for designers as it allows you to fully test and alter models before bringing your digital design to life in the form of a physical object. It can also be used to design objects such as jewelry, furniture, appliances, etc.

What’s the Difference Between Parametric and Direct Modeling? - ENGINEERING.com

What’s the Difference Between Parametric and Direct Modeling?.

Posted: Mon, 05 Mar 2018 08:00:00 GMT [source]

3D Printing Industry Statistics (2024 Update)

It facilitates collaboration among multidisciplinary teams working on a project, leading to better-designed and more efficient solutions. It offers a range of tools and features for creating wireframes, mockups and prototypes. Adobe XD includes UI libraries, interactive design tools and collaboration features. CAD (computer-aided design) is the use of computer-based software to aid in design processes. CAD software is frequently used by different types of engineers and designers.

This method enables easy modification and adaptation of designs, offering flexibility and control over various design elements. CAD is used in product design to create digital prototypes, perform virtual testing, iterate on designs, and ensure manufacturability and functionality before production. Overall, CAD solutions have greatly enhanced the capabilities of mechanical engineers, allowing for the efficient design, simulation, and optimization of mechanical components. With continued advancements in CAD technology, the future of mechanical engineering looks bright. CAD solutions have revolutionized the architecture and construction industries, streamlining processes and enabling professionals to create detailed designs with greater efficiency and accuracy.

Perhaps this person is putting up drywall, hammering nails, laying flooring, or even having lunch high above the ground, evoking the iconic Lunch Atop a Skyscraper photograph. Although all these constitute part of the job, construction is in many ways a tech job. This has always been the case — but with the introduction of computer-aided design (CAD), technology’s role in the industry and the impact it has on the job have both grown. MCAD (mechanical computer aided-design) systems introduced the concept of constraints that enable the designer to define relations between different components in the assembly. Sutherland demonstrated the basic principles and feasibility of technical drawing using a computer. The 3D Wireframe model is an edge or skeletal representation of a real-life object.

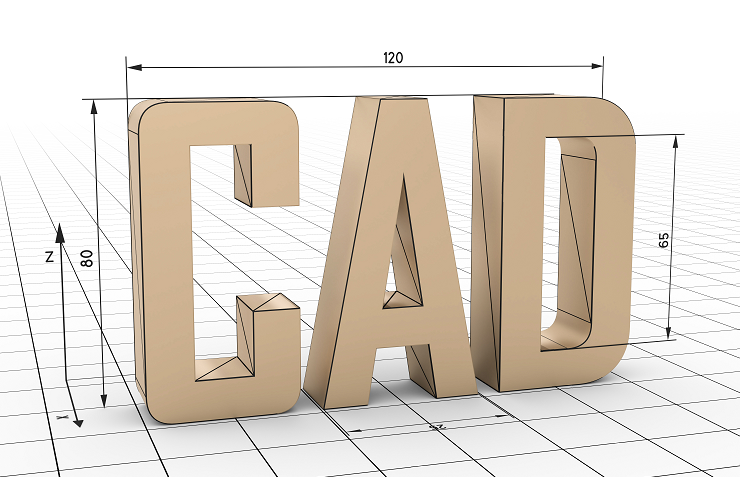

As technology continues to advance, the capabilities of CAD are set to grow even further, enhancing the design process and contributing to the creation of better, more innovative products. CAD, or Computer-Aided Design, as we’ve explored, involves using computer software to create, modify, analyze, or optimize a design. It is predominantly used in the design stage of a product’s lifecycle, turning conceptual design into detailed, technical drawings and 3D models. It ensures that designs are precise, amendable, and ready for production or construction. CAD software is used by designers and engineers to develop 2D drawings and 3D models of products they aim to create.

Basic geometric representations of objects are made with it, giving additional modeling a visual foundation. Wireframe CAD is more straightforward and uncomplicated than solid or surface modeling; yet, it is devoid of realistic rendering capabilities and comprehensive surface information. Direct Modeling CAD software offers a more flexible approach to design, allowing users to manipulate geometry directly, without the need for predefined parameters or constraints. With direct modeling, designers can easily make quick modifications to their designs, exploring different iterations and variations on the fly. Designers may quickly experiment with different iterations and variants of their designs by modifying them with direct modeling. This kind of CAD is very helpful for rapid prototyping and idea modeling, in which it's critical to iterate designs quickly and nimbly.

3D CAD allows engineers and architects to view and manipulate their designs from different angles, giving them a better understanding of how the final product will look and function. Sketch is a popular CAD program known for its ease of use and powerful design tools. It includes a range of features for creating wireframes, mockups and prototypes. CAD software helps designers create accurate visual representations of user interfaces, including their layout, navigation and functionality. These functionalities help designers understand how users will interact with a product, and identify potential problems or opportunities for improvement.

The program helps simplify the modeling of plant components, including piping and support structures. The software offers a number of tools to deal with typical plant and process design challenges, such as the standardization and customization of parts for a particular project. It also improves accuracy as well as increases design and engineering productivity as typical challenges are addressed when building the model.

CAD software makes it possible for these professionals to also modify and optimize designs easily and intelligently. CAD software offers designers the tools to create digital models of products that can be tested and optimized before they go into production. With these benefits in mind, it’s easy to see why CAD has become an essential tool in modern design processes. Whether you’re working in architecture, product design, mechanical engineering, or any other industry that uses design, CAD is a powerful tool that can help you create better designs more efficiently. CAD (Computer-Aided Design), is a digital technology that enables the creation, modification, and optimization of designs using specialized software. It involves the use of computer systems to generate precise and detailed two-dimensional (2D) or three-dimensional (3D) models that can be easily manipulated and visualized.

No comments:

Post a Comment